Industrial Metal Fabrication Projects Across Canada

At Nu-Tech, we tackle the metal fabrication projects others avoid.

Big, custom jobs with no room for error. Our team designs, builds, and installs steel systems that power industries across Canada. Be it mining, agriculture, food processing, or heavy industry, we have done it all.

Each project comes with its own challenge. We solve it fast and do it right. Our portfolio includes detailed sheet metal work, full structural installs, and heavy structural steel systems. No outsourcing or delays.

Nu-Tech has led more than one steel building project in tough terrain. We also deliver rigid steel building projects for remote and industrial environments.

Delivering Complex Metal Fabrication Projects with Precision

Our experienced team of experts designs, builds, and installs full systems for demanding sites. All operations are handled in-house, from early drawings to final welds.

We have successfully completed large-scale metal fabrication projects for mining, food processing, and industrial plants. This includes HVAC ducting, sheet metal work, and structural ventilation systems. We also support site-specific containment projects where safety, airflow, and dust control are crucial.

Magino Mine – Argonaut Gold, 2023

Nu-Tech provided fabrication for crusher dust collection and HVAC across the Magino mill site. This entailed large ducting, steel cladding, and sheet metal enclosure. These systems support safe ventilation and reduce airborne particles during crushing.

Magino Mine is one of our complex metal fabrication projects, involving round-the-clock coordination. It also fits into our rapidly growing list of containment projects, designed to meet stringent air quality and safety requirements.

New Gold – Rainy River Mining Complex, 2017

The New Gold project focused on full ventilation and on-site containment system fabrication. Our crew designed and installed custom ductwork to control airflow inside the processing plant.

These builds required structural framing and corrosion-resistant materials. The mining complex also added to our portfolio of high-performance containment projects where durability and airflow were key.

Nutrium – Vanscoy Potash Refinery, 2014

Nu-Tech fabricated extensive ducting systems and process ventilation for this high-output potash facility. The work involved precision sheet metal and structural support frames across multiple buildings.

As one of our earlier large metal fabrication projects, it set the standard for refinery-based ductwork we now deliver across the country. Custom fittings, tight timelines, and strict safety specifications drove every decision.

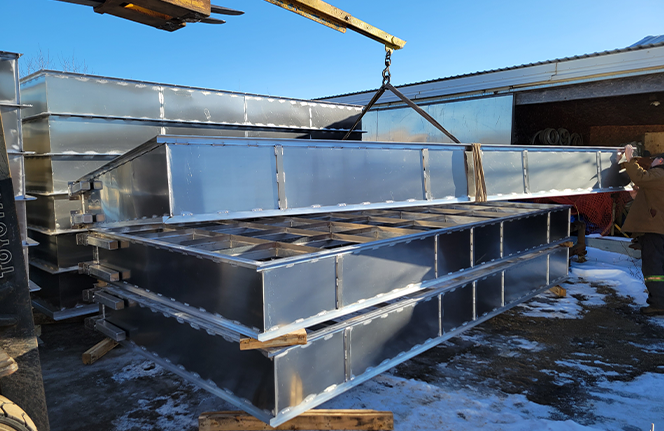

Canada Malting – Storage Tank Project, 2021

The Nu-Tech team designed and installed full stainless steel storage tanks at the Thunder Bay processing facility.

This project required unique metal curved skin tanks, engineered for wind, water, and long-term exposure. The Canada Malting metal fabrication project combined structural integrity with clean and functional design.

Steel Building Projects for Industrial and Commercial Clients

Building strong steel structures in high-demand industries is one of our specialties. Every steel building project is engineered for durability and long-term use. We are also the go-to factory for rigid steel building projects in the mining, agriculture, and industrial storage sectors.

Our buildings are pre-engineered structures with no structural steel. The walls are engineered to support the roof loading, making these buildings ideal for remote applications where cranes and transport vehicles can’t access. Rigid steel buildings are 28ft maximum in width. They can be however long you need, and have a maximum wall height of 14ft.

Our buildings go up quickly and withstand tough weather. For industries requiring customized layouts for equipment, workflow, or multi-use spaces, Nu-Tech delivers.

Rigid Steel Building Projects in Remote and Industrial Zones

All deliveries are structured for ease. Our team plans every detail, including transportation, staging, and site preparation, to ensure seamless remote work. We have also completed rigid steel building projects in the North, on mine sites, and deep in forestry zones.

Every job runs as a full-service steel building project, from design to final bolt. Even in remote zones, we stick to the schedule and specifications.

Structural Support and Modular Building Integration

Nu-Tech combines structural steel with modular layouts for faster delivery and easy expansion. Each module fits cleanly into the larger framework. This approach speeds up installation without sacrificing strength.

We typically incorporate these into rigid steel building projects where space requirements change rapidly. As part of a larger steel building project, it saves time, cuts costs, and adds flexibility.

Specialized Containment Projects for Industrial Facilities

Nu-Tech specializes in creating custom sheet solutions for hazardous zones, heavy dust, and critical airflow control. Every detail matters, including duct shape and final seal.

We lead containment projects that protect workers, equipment, and air quality. Each build meets site-specific standards. Our crews work with engineers on layouts, load ratings, and system flow. Safety is engineered in.

Custom-Built Containment Ducting and Hoods

Mines and processors kick up serious dust. We contain it. Our team builds large ducting systems, steel hoods, and sealed enclosures around crushers, mills, and conveyors. Multiple containment projects have been completed, mostly focused on dust control and filtration. Every hood and pipe is part of broader metal fabrication projects, shaped and welded for an exact fit.

Seamless Integration with HVAC and Ventilation Systems

We don’t bolt on systems; we build them in. Nu-Tech’s containment projects connect with your HVAC, ducting, and fans without disruption. The design for airflow is sleek, alongside pressure and access. Every vent, damper, or flange lines up where it should. This is how we avoid pressure loss, flow blockages, or maintenance gaps.

Long-Term Durability for Harsh Operating Conditions

When we are set to work, we plan for everything. This includes harsh heat, corrosive vapours, and heavy grit. Our containment projects use coated steel, lined ductwork, and thick-gauge metals that hold up over time. These systems don’t break down or rust out. We fabricate for extreme zones, dryers, kilns, acid tanks, and hot lines.

Experience, Precision, and Reliability You Can Count On

For decades, we have led metal fabrication projects and complex builds across Canada. Our team handles every step, such as design, fabrication, and installation. We keep timelines tight and results sharp. From mining sites to food plants, we adapt to any job. Every steel building project or custom duct run fits the real-world needs of each client.

Decades of Proven Success Across Industrial Sectors

Clients return to Nu-Tech because we consistently deliver exceptional results. Whether the project is large or small, our metal fabrication solutions are designed to withstand pressure, load, and the test of time. Each steel building project is managed with complete oversight, ensuring every detail is executed flawlessly from start to finish.

Skilled Tradespeople and Advanced Fabrication Facilities

We invest in our people and our tools. Skilled welders, CNC tables, 3D modelling, clean lines, tight welds, zero delays. It shows in every job, from vent systems to full rigid steel building projects.

Customer-Focused Approach from Start to Finish

From first to final bolt, we build and listen. Nu-Tech makes your priorities ours. Clients rely on us for smooth metal fabrication projects, on-site updates, and reliable coordination. Our team delivers rigid steel building projects with speed and attention to detail.

Partner with Nu-Tech on Your Next Fabrication or Steel Building Project

Bring your build to life with a team that gets it done right. Nu-Tech handles complex metal fabrication projects and full-scale builds with speed, skill, and precision. In the drawing and final install, we keep your goals front and center. Budget, timeline, and scope are covered.

For factories in need of a custom steel building project, our team designs, builds, and supplies it. We also manage full rigid steel building projects with zero guesswork.

Our factory is equipped, and our experts are ready to work. Reach out to us today at +1 807-798-1127 or contact us online. We are the team industrial clients trust across Ontario and beyond.