Did you know that even a short drop in temperature can spoil millions of dollars’ worth of products stored in cold rooms? Industries like food processing, pharmaceuticals, and logistics depend on reliable cold rooms to keep goods safe and compliant.

Insulated panels change this narrative by delivering airtight seals. When paired with strong metal wall systems, they form a shield against shifts in temperature. This combination cuts energy waste and keeps operations running smoothly.

Beyond just insulation, these panels reduce maintenance needs and help facilities avoid costly shutdowns. The right panels make cold rooms safer, more efficient, and built to last.

Here are five key benefits that show how insulated metal panels can transform cold storage.

1. Thermal performance for optimal temperature control

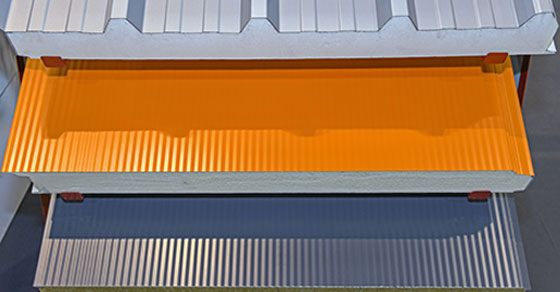

Insulated panels form a continuous layer that slows heat transfer. Inside, the core is made from materials like polyurethane (PUR) or polyisocyanurate (PIR). These rigid foam types consist of tiny gas-filled cells. The trapped gas reduces heat movement and maintains steady temperature control inside.

Next, the panel’s design includes tightly locking edges. These joints form airtight seals, preventing drafts and stopping thermal bridging—points where heat could bypass insulation through gaps or framing.

Finally, the stable environment created by insulated panels reduces the strain on refrigeration equipment. Cooling systems run less frequently and with less intensity. This lowers energy consumption and cuts operating costs over time. The savings gained through temperature control can offset the initial cost of the panels.

2. Durable metal wall systems for harsh environments

Metal wall systems stand up to the toughest conditions found in cold storage facilities.

For instance, cold rooms face moisture, chemicals, and constant temperature swings. These changes can quickly damage standard building materials.

High-quality insulated panels use metal facings that resist corrosion and physical wear.

- For moisture: Condensation forms when warm air meets cold surfaces. Metal wall systems with proper coatings prevent water from seeping in and causing damage.

- For chemicals: Resistance to chemicals is important in industries like pharmaceuticals and food processing, where cleaning agents and spills are common. These metal wall systems around panels withstand harsh sanitizing processes without degrading.

Durability is another major advantage. Facilities can operate continuously without cost interruptions. This reliability is essential for cold storage in the logistics, biotech, and food sectors.

Additionally, investing in strong metal wall systems reduces repair expenses and protects valuable inventory. Cold rooms also stay efficient and safe for years to come.

3. Quick building setup reduces time and costs

Insulated panels are produced off-site in climate-controlled factories, so you get consistently high-quality units delivered ready to install. By combining the structural frame, insulation, and exterior finish into one product, crews can skip separate framing, insulating, and cladding phases, and begin assembly immediately.

Thanks to factory-precision cutting, each panel fits exactly as designed, cutting down on field modifications. The outcome is a faster, smoother build with fewer delays and surprises.

In essence, faster construction means projects finish sooner. Completing work early reduces financing fees and overhead costs. Prefabricated insulated panels help keep cold storage projects on time and within budget.

4. Improved hygiene and sanitation for food and pharma cold rooms

Insulated panels have smooth and sealed surfaces that prevent dirt, moisture, and bacteria from accumulating. Such surfaces reduce contamination risks in cold rooms, mostly in sensitive food processing and pharmaceutical environments.

For example, metal wall systems create a porous barrier without cracks or gaps where germs could thrive. Panels can also resist stains and withstand frequent cleaning with strong sanitizing agents.

These qualities help maintain the strict sanitation routines needed for cold rooms. This also helps industries stay compliant with health regulations and other public health industry standards.

5. Customizable solutions to meet specific facility needs

Apart from being the go-to option for peak thermal performance, durability, and compliance with health standards, insulated panels offer flexibility in thickness, finishes, and sizes.

For instance, they can integrate easily with doors, windows, and other cold room accessories. Custom fitting creates airtight seals around openings, preventing temperature loss and maintaining consistent temperature control.

Well-designed placements of these elements also support workflows and boost safety.

Flexibility also extends beyond initial installation. Modular metal wall systems allow for adjustments and future expansions. Facilities can easily respond to changing demand without expensive renovations.

Contact Nu-Tech Metals for Quality Insulated Panels

Building a cold storage facility can be compared to assembling a complex machine: every part must fit perfectly and work reliably. Nu-Tech Metals has extensive experience in producing tailored insulated panels that cater to the unique requirements of every cold storage initiative.

As a trusted and popular fabrication company, we make sure each panel meets strict quality standards. The metal wall systems will withstand the harsh Canadian climate while supporting the facility’s structure.

Our engineering team is committed to quality of craftsmanship, on-time delivery, and strict budget control. Customer satisfaction drives every project from start to finish.

To discuss insulated panel projects or request a quote, call Nu-Tech Metals today at +1 807-798-1127 or contact us online. We will deliver cold storage systems that are functional, flexible, and built to last for years.